In the field of precision manufacturing, standard blades are widely applicable, and the product quality ladder is large. Zhengzuan insists on high-end precision manufacturing market segmentation, grasps quality from the source of material technology, optimizes and improves the edge and blade body with 24 years of experience and practical feedback from the front line, and the complete maturity of supporting services to create high-end standard blades, so that customers can experience the value of Zhengzuan with a single blade.

Zhengzuan has the world's advanced sharpening equipment, high-precision spindle system and clamping system, high-precision rotary function to ensure that the grinding wheel jump when high-speed rotation; grinding wheels are selected from high-quality ceramic and resin grinding wheels to effectively control the edge chipping; raw materials are imported composite pieces to ensure stable and uniform product quality between different batches.

From production to delivery to customers, each batch and each tool needs to go through heavy quality inspection, and only after passing the strict test results are correct before packing and delivery. High-quality raw materials and mature technology have established the high-end quality of Zhengzuan's tools from the root.

2.edge enhancement

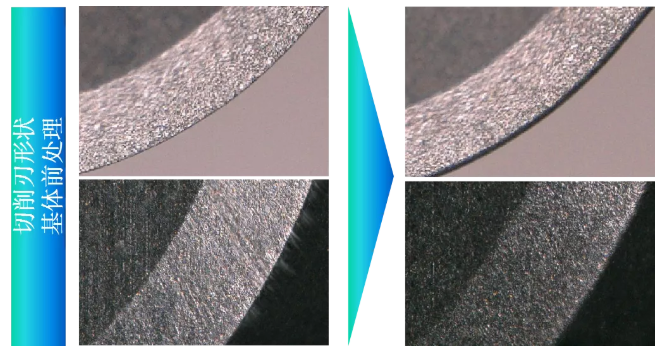

In the 24 years of high-end tool manufacturing, Zhengzuan has been exploring the edge enhancement technology and process, and found that the actual edge formed by grinding or other methods in the tool manufacturing process is not the ideal sharpness. In response to this problem, Zhengzuan has enhanced the cutting edge of the tool through the field experience and cutting data accumulated over the years.

Zhengzuan PCBN standard tools can do a variety of edge treatment, standard tools generally do not do edge treatment, but under special conditions can do appropriate edge chamfering and other treatment to meet the processing needs. The edge enhancement can eliminate the edge and edge micro-zone defects, and obtain the appropriate edge micro-geometry parameters, edge surface morphology and surface micro-weaving, and eliminate residual stress, which can improve the edge strength, enhance the coating adhesion, improve the stability of cutting process, improve the edge wear resistance, and finally improve the tool life and stability.

3.Chipbreaker

Chip breakage is unavoidable in cutting process, and it will directly affect the efficiency and quality of cutting process. Based on the feedback from customers' actual cutting cases, Zhengzuan has continuously innovated and upgraded the technology and techniques by using long-term technical accumulation to add different chipbreaking slots on the standard inserts to achieve efficient chip control and chip removal during the machining process. Reduce the impact of chip breakage on the tool and machining workpiece, reduce the scrap rate and improve the machining efficiency.

4.Coating

In order to meet the needs of high precision, high difficulty and high efficiency machining environment, Zhengzuan adds coating process on the basis of PCD/PCBN standard insert edge enhancement and chipbreaking groove process. The strong adhesion makes the coating not easy to fall off and realize stable processing. And after adding the coating, the tool wear resistance is significantly improved, thus extending the life, and the coating also brings lower surface roughness to meet the needs of high-precision machining.

5.Added value

"High-end" is not only limited to the product itself, but also contains invisible product services and added value.

Zhengzuan provides a one-stop technical support program from the preliminary consultation to the late tool inspection. And for the accumulated processing time, the edge chipping, wear brought about by the inaccuracy of precision reading, efficiency reduction and other problems to provide tool recycling services, the edge of the worn tool can be resharpened or replacement services. The tool life can be restarted to effectively reduce costs and increase efficiency for customers, save energy and reduce the consumption of non-renewable resources.

Zhengzuan PCD/PCBN standard inserts, from the product itself, to additional services, layers of strict control of the process, each process excellence, only for better cutting experience, better product performance. With the development of technology, Zhengzuan Tools will continue to optimize and create value in the field of high-end precision manufacturing with technological innovation and high quality service.

No.198,the 7th Avenue of Zhengzhou Economic and Technological Development Zone,

Zhengzhou,Henan,P.R.C